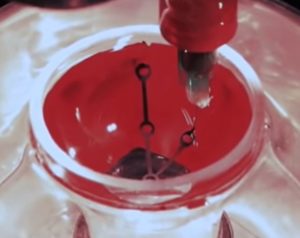

Starting with a bowl-shaped glass substrate around 20mm in diameter, the team printed a silver nano-particle-based ink, extruding it through a fine nozzle on a custom-made 3D printer – see image. “The dispensed ink stayed in place and dried uniformly instead of running down the curved surface,” said the University.

|

Wherever photo-diodes were needed (in this case, into the holes in the silver tracks), the conductive polymer PEDOT:PSS was printed, followed by the polymer P3HT:PCBM which dries into a bulk-type semiconductor junction. This combination of PEDOT:PSS and P3HT:PCBM layers is a well-known route to organic photo-cells.

Finally, each junction was topped with a spot of eutectic gallium-indium (which is liquid at just above room temperature) as a top electrode – just visible in the left image.

|

“We have a long way to go to routinely print active electronics reliably, but our 3D-printed semiconductors are now starting to show that they could potentially rival the efficiency of semiconducting devices fabricated in microfabrication facilities,” claimed researcher Michael McAlpine . “Plus, we can easily print a semiconducting device on a curved surface, and they can’t.”

According to the abstract of ‘3D printed polymer photodetectors‘, a paper in Advanced Materials, the external quantum efficiency of the photodiodes is 25.3% despite being printed in ambient conditions without a cleanroom.

The curved surface is similar to the inside of the human eye, and McAlpine’s next steps are towards something like an artificial retina – creating a prototype with more, more efficient, light receptors, plus developing a way to print on a soft hemispherical material that can be implanted into a real eye.

To demonstrate the printing of a functional electronic component, the team also printed an optically-coupled photo-detector and LED.

Source from:electronicsweekly

Englisch

Englisch  Chinesisch

Chinesisch  Deutsch

Deutsch  Koreanisch

Koreanisch  Japanisch

Japanisch  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  Spanisch

Spanisch